Configure finished product to the International Organization for Standardization. Identify your finish product and we develop a quote and recommend the appropriate tungsten carbide blank.

Unit of Measure

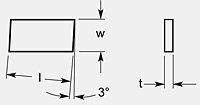

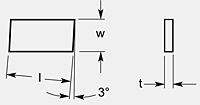

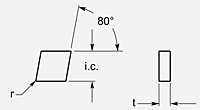

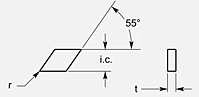

Classifications

-

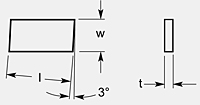

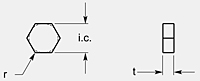

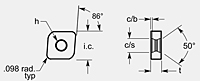

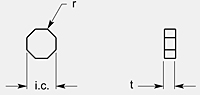

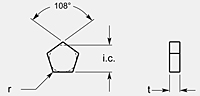

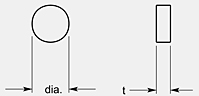

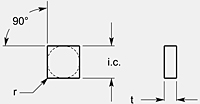

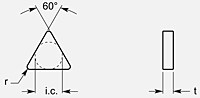

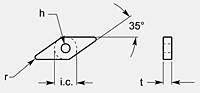

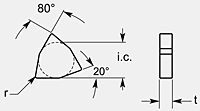

1 I.C. GRIND STOCK ALLOWANCES

FOR I.C. SMALLER THAN 1" = 0.014 / 0.020

FOR 1" I.C. AND LARGER = 0.020 / 0.030

TRIANGLES = 0.017 / 0.030

I.C. TOLERANCES = ±0.002 - ±0.010

All grindstock allowance and tolerance ranges vary depending on blank size.

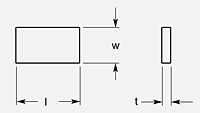

THICKNESS GRIND STOCK ALLOWANCES

FOR I.C. SMALLER THAN 1" = 0.010 /0.018

FOR 1" I.C. AND LARGER = 0.017 / 0.023

Variable thickness available on all negative peripheral blanks.